DIGITbrain H2020 Innovation Action to Enable SMEs to Benefit From Digital Twins

DIGITbrain Project is an European innovation project aimed at revolutionizing the manufacturing industry by providing an accessible, modular, and collaborative platform for faster development of Digital Twin solutions. By empowering manufacturing companies to optimize their operations using Digital Twins, DIGITbrain seeks to unleash their innovation potential and improve their competitiveness in an increasingly digitalized world.

The DIGITbrain Approach

In concrete, the DIGITbrain approach aims to facilitate the distribution and utilisation of digital twins in the manufacturing industry by the following steps:

-

- the provision of a modularised approach utilizing preconfigured components to facilitate and accelerate the development and customization of Digital Twins.

- the augmentation of the Digital Twin concept to a smart, self-preserving entity that‘s equipped with memorizing, decision and support capabilities.

- the implementation of the Manufacturing as a Service business model, which provides utmost flexibility for manufacturers who can remotely access manufacturing machines they need and new business opportunities for machine providers.

Digital Twins for Manufacturing

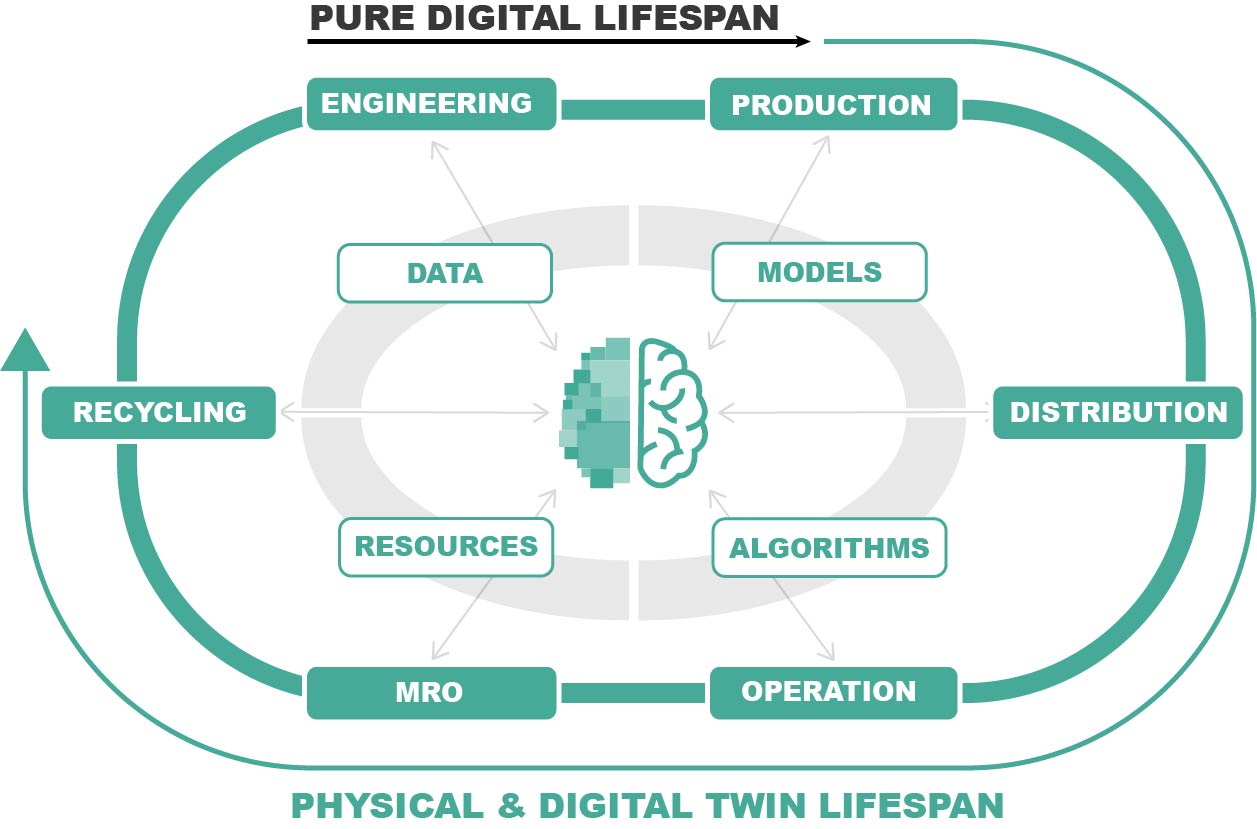

A Digital Twin is the virtual representation of a product, system or process that simulates its physical attributes in the real-world in real time. By collecting data from its physical counterpart, manufacturers are enabled to streamline the manufacturing process and make predictions with regard to machine failures or maintenance needs. Compared to the traditional concept of the digital twin, as it is already increasingly used by manufacturing companies today, the DIGITbrain concept goes one step further.

The Digital Product Brain

By expanding the concept of a digital twin to a smart entity, which is empowered with analysis and decision-support capabilities, as well as a memorizing capacity that stores all data from the entire life-cycle of an industrial product or machinery, DIGITbrain represents an evolution of the digital twin concept: the Digital Product Brain (DPB).

The combination of gathered data with dedicated models within the different stages of the product lifecycle empowers the industrial product with an adaptive capacity that unlocks completely new scenarios. For instance, it enables the possibility to remotely steer and optimize the behavior and performance of the machine according to the operating conditions. By doing so, the Digital Product Brain provides the basis for the Manufacturing-as-a-Service (MaaS) business model.

Manufacturing as a Service

The Manufacturing as a Service business model is interesting for manufacturers and manufacturing machine providers alike, as it will enable them to create additional revenue streams and be more competitive turning their CapEX into OpEX. Manufacturers benefit by ourtsourcing parts of their production which they can remotely monitor and validate through digital twin-based solutions. Manufacturing machine providers will obtain the opportunity to open up a new business model by monetizing their unused capacity and licensing the digital twin solution related to their equipment rented.

Do you want to learn more about the benefits of the Digital Brain?

Let's get into a conversation!

contact@digitbrain-dev.innen.it

The EU project has been funded through the Horizon 2020 Research and Innovation Programme by the European Commission under grant agreement number 952071 for a duration of 3.5 years. PNO Consultants are coordinating the project. Overall, the innovation project, which began on July 1st, 2020, will receive 8.34 million euros to enable a facilitated way to digital twins for manufacturers and prove the project's approach by implementing 21 application experiments over its lifetime. After two open calls that invited participation in the experiments, the DIGITbrain project now unites a consortium of 73 partners, including well-known research organizations, universities, manufacturing technology/software providers, manufacturers, and Digital Innovation Hubs that help facilitate collaboration among the experiments.