Motivation of the Experiment

Considering the context of the fourth industrial era, Industry 4.0, REPLASA has started its transformation towards a smart factory, testing new technologies like Artificial Intelligence and Cloud Computing. Among the different strategies designed to be implemented in the forthcoming years, an intelligent energy management system for the production lines was defined as one of the main lines of work, due to the high cost that is associated to the energy consumption (that can be as high as 5% of the total product cost). Reducing energy consumption in the production line could have a high impact in the cost of the manufactured product and thus in its competitively in the market. For this reason, achieving a significant reduction of the energy consumption has been established as a priority for the company.

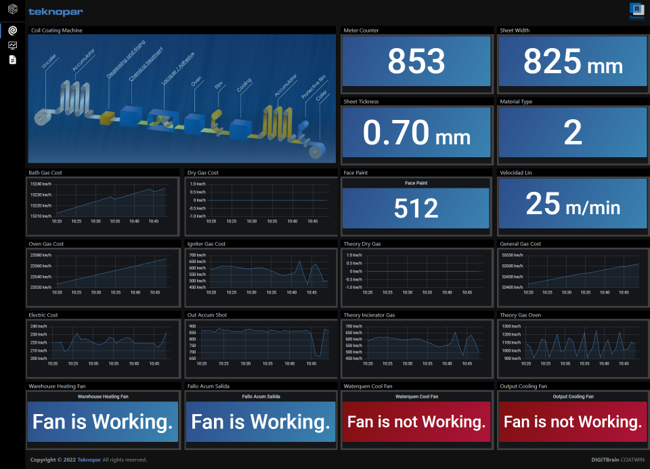

The energy consumption of the line is associated to electricity (mechanical and electronic parts of the line), natural gas (heating and cooling elements of the line), and compressed air (pneumatic parts of the line). The management of the parameters (such as speed of the line, temperature of the oven, intensity of the cooling system) of these elements is complex and are different depending on the final product. Currently, REPLASA does not have any tool (example: a simulation model) allowing to change the production parameters and assess the impact of those changes in the energy consumption. In general, the optimization of the coil coating line is a real challenge for the company and there is not a simulation or model of it. Within this context, in its Digital Transformation plan REPLASA has identified the potential of Digital Twins for the optimization of production lines. For this particular need, a Digital Twin with Artificial Intelligence capabilities would allow REPLASA to create a twin of the coil coating line and, when properly trained, it has the model energy consumption, make simulations and lead to decentralized decisions.

Purpose of the Experiment

The plan of TEKNOPAR is to use the Cloud and HPC resources from the DIGITBrain Platform, and later on deploy the services (data, model and algorithms) to be developed within the proposed project on to the Cloud of the DIGITbrain platform or on premise server of REPLASA. It will be necessary to train the algorithms using the HPC resources and utilize MarketPlace of the Digital Agora to publish the results achieved.

The IIoT platform will be verified and validated for a new set of assets (sensors, actuators, PLCs, data sources, etc.) and will further be tested for scalability, security and flexibility in a different industrial setting. TEKNOPAR’s machine learning library will include new algorithms for predictive maintenance used to estimate RUL of the machinery of line, TEKNOPAR’s synthetic data generator (DATA-GEN) will be used in a new setting as an authoring tool with Docker virtualization means. A completely new cognitive digital twin for the production line will be generated, additional features in visualisation are expected to be implemented.

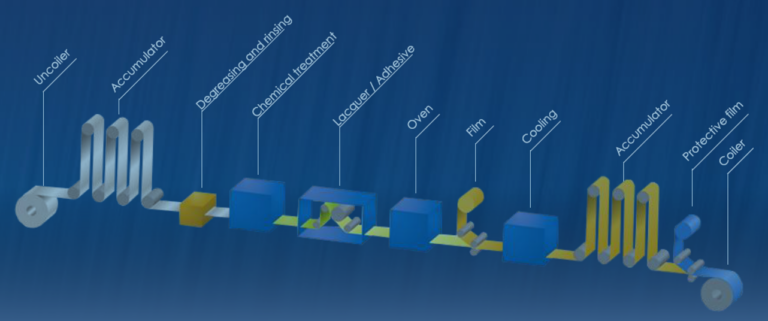

Coil coating industrial line

Technical Impact

REPLASA does not have any tool allowing to change the production parameters and assess the impact of those changes in the energy consumption so the development of an intelligent system, based on AI techniques and machine/deep learning will allow REPLASA to control the consumption in real time while establishing the best production parameters to optimize the consumptions (gas, electricity and compressed air). Moreover, it will allow to make simulations and predictions of such consumptions, allowing decision making.

Currently there are no sensors installed on the coating line (will be installed during the experiment). The information REPLASA can get from the PLC comes from the data of the frequency convertors of the motors, but no data collection or storage occurs. Therefore, the design and implementation of a digital twin will mean a step forward in the company's digitization process. Starting from scratch, the possibilities for future growth are high, also giving rise to potential collaborations with TEKNOPAR both in the short and medium term. By this, we can say that for TEKNOPAR, the main impact includes a software product innovation opportunity: the cognitive digital twin developed for the coating line will be a new product/service developed by TEKNOPAR, which will enhance the existing software elements (the required sensors/data sources will be new additions to the existing IoT platform). The new algorithms and models may be added to existing machine learning predictive maintenance and energy optimization library of TEKNOPAR. In addition, all the components in the project will run on the Cloud or on premise server, and the Quality attributes (performance, flexibility, portability, scalability) of the existing blocks are aimed to be improved in the proposed project.

Dashboard

Economic Impact of COATWIN Experiment

TEKNOPAR has a large customer base where IoT and digitalization technologies are in high demand. The company has publicly funded projects on digitalization of industry with sensor networks and control platforms, that are exploited with patents and utility models. TEKNOPAR has developed digital twins for the product lifecycle to simulate, predict, and optimize the product and production systems and has worked with combining data, physics- based models, machine learning (ML), Artificial Intelligence (AI) in the best possible ways to solve industrial challenges. Among the digital twins generated by TEKNOPAR, one can list digital twins (model driven digital twins), hybrid twins (composed of both data and model driven digital twins), and AI enhanced cognitive digital twins. DIGITbrain, enabled TEKNOPAR to make a digital twin application on a novel cloud platform that can be easily adopted according to the needs of the customers, thanks to its flexible architecture consisting of data, models and algorithms. In addition, DIGITbrain integration has enabled TEKNOPAR to offer our product to a new customer base through the marketplace platform, Digital Agora.

Fatih Yallıç, Computer Engineer, TEKNOPAR.

"DIGITbrain, enabled us to make a digital twin application on a novel cloud platform that can be easily adopted according to the needs of the customers, thanks to its flexible architecture consisting of data, models, and algorithms. In addition, DIGITbrain integration has enabled us to offer our product to a new customer base through the marketplace platform, Digital Agora."

Project Partners

REPLASA

is the end-user in this

experiment.

Teknopar

serves as the data model & algorithms provider.

ITAINNOVA

is the Digital Innovation Hub with the role of experiment supervisor.